H544K

Share

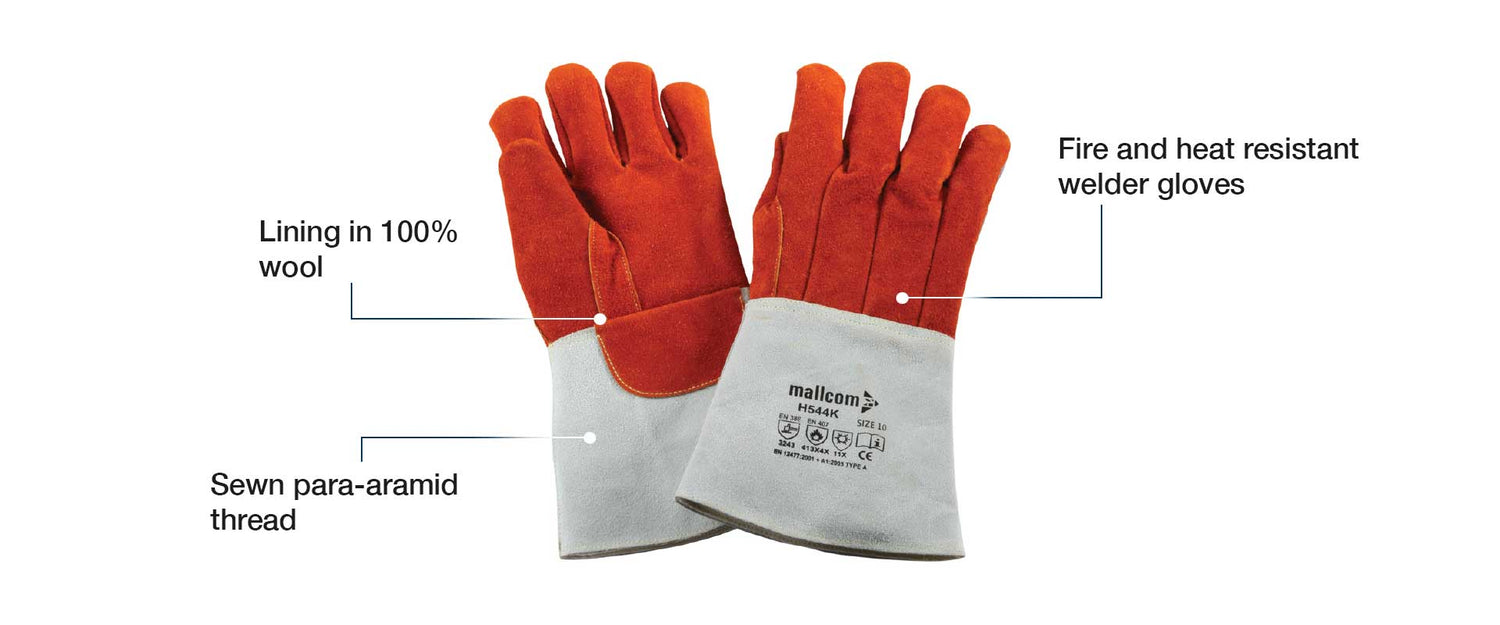

HEAT RESISTANT WELDER GLOVES

- Fire and heat resistant welder glove

- Lining in 100% wool Sewn para-aramid thread

- Heat resistant up to 100 degrees c (for 15 sec)

Abrasion

Heat Resistant

EN 388:2016+A1:2018

EN 407:2020

EN 511:2016

EN 12477:2001+A1:2005

RESIST 100 *C CONTACT HEAT FOR 15 SECONDS

Delivery & Services

Easy Return

with our 15 days return poicy

Regular price

Rs. 0

Sale price

Rs. 0

Regular price

Tax included.

Shipping calculated at checkout.

ABOUT THE DESIGN

USEFUL IN THESE INDUSTRIES

AUTOMOBILE

IRON & STEEL

METALLURGY

REPAIRS & MAINTANENCE

Product Features

ABOUT THE DESIGN

USEFUL IN THESE INDUSTRIES

AUTOMOBILE

IRON & STEEL

METALLURGY

REPAIRS & MAINTANENCE

Product Details