NF153G (PACK OF 4)

Share

Synthetic Gloves

-

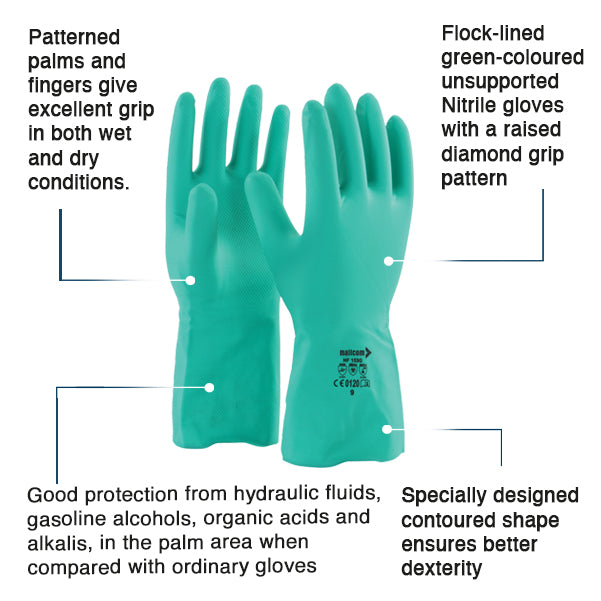

SUPERIOR PROTECTION AND GRIP - The flock-lined green nitrile gloves offer exceptional protection against a range of substances, including hydraulic fluids, gasoline, alcohols, organic acids, and alkalis. Their raised diamond grip pattern ensures excellent grip in wet or dry conditions. The contoured shape enhances dexterity, making them ideal for various tasks, from industrial work to outdoor activities

-

COMFORT AND ABSORPTION - Designed for comfort during prolonged wear, these gloves feature a cotton flock-lining that absorbs perspiration, keeping hands dry and comfortable. The ergonomic design reduces hand fatigue, allowing for extended use without discomfort. Whether working in hot or cold conditions, the lining provides an added layer of insulation, enhancing overall wearability

-

NBR MATERIAL COMPOUND - Crafted from NBR material compound, these gloves are oil-resistant, water-resistant, and resistant to chemical splashes. This ensures durability and longevity even in demanding environments. The material's resilience against various substances makes these gloves a reliable choice for tasks where protection is paramount, such as in industrial settings.

Oil Resistant

Water Resistant

Chemical Splash

CE

EN 388+A1 4102X

EN ISO374-5

Delivery & Services

Easy Return

with our 15 days return poicy

ABOUT THE DESIGN

USEFUL IN THESE INDUSTRIES

AGRICULTURE

PHARMACEUTICAL

CHEMICAL & PAINTS

HOSPITALITY

OIL & GAS

Resistance to abrasion based on the number of cycles required to abrade through the sample glove (abrasion by sandpaper under a stipulated pressure). The protection factor is then indicated on a scale from 1 to 4 depending on how many revolutions are required to make a hole in the material. The higher the number, the better the glove.

Blade cut resistance based on the number of cycles required to cut through the sample at a constant speed. The protection factor is then indicated on a scale from 1 to 5. Tear as per EN 388 is 0: Tear resistances based on the amount of force required to tear the sample. The protection factor is then indicated on a scale from 1 to 4.

Puncture resistances based on the amount of force required to pierce the sample with a standardly sized point. The protection factor is then indicated on a scale from 1 to 4.

The glove sample is placed on a conductive strip and loaded onto the TDM-100. When the metal blade touches the metal strip, the test is terminated. A straight blade is loaded into the machine. Weight is added to serve as a force. The blade moves across the fabric. The blade is replaced with a new one to ensure accuracy. The sample is cut five times, each with three different loads. The distance traveled to cause cut through at various forces is recorded. The data is used to determine the load required to cut through the sample.

Product Features

ABOUT THE DESIGN

USEFUL IN THESE INDUSTRIES

AGRICULTURE

PHARMACEUTICAL

CHEMICAL & PAINTS

HOSPITALITY

OIL & GAS

Product Details

Tests

Resistance to abrasion based on the number of cycles required to abrade through the sample glove (abrasion by sandpaper under a stipulated pressure). The protection factor is then indicated on a scale from 1 to 4 depending on how many revolutions are required to make a hole in the material. The higher the number, the better the glove.

Blade cut resistance based on the number of cycles required to cut through the sample at a constant speed. The protection factor is then indicated on a scale from 1 to 5. Tear as per EN 388 is 0: Tear resistances based on the amount of force required to tear the sample. The protection factor is then indicated on a scale from 1 to 4.

Puncture resistances based on the amount of force required to pierce the sample with a standardly sized point. The protection factor is then indicated on a scale from 1 to 4.

The glove sample is placed on a conductive strip and loaded onto the TDM-100. When the metal blade touches the metal strip, the test is terminated. A straight blade is loaded into the machine. Weight is added to serve as a force. The blade moves across the fabric. The blade is replaced with a new one to ensure accuracy. The sample is cut five times, each with three different loads. The distance traveled to cause cut through at various forces is recorded. The data is used to determine the load required to cut through the sample.