P35NBG

Share

Seamless Nitrile Gloves

-

ADVANCED CONSTRUCTION for MAXIMUM PROTECTION - Seamlessly constructed with a 15-gauge grey polyester seamless liner and featuring a sandy finish black NBR palm coating, these gloves offer advanced protection against abrasion. The durable construction ensures longevity, making them ideal for prolonged use in demanding environments. Whether you're working on production floors, biking, or engaging in outdoor adventures

-

HAZARD RESISTANCE FOR SAFETY ASSURANCE - Engineered to resist hazards associated with hydrocarbons, oil, and slips, these gloves prioritize safety in the workplace. The robust design offers reliable protection against potential risks, providing peace of mind during tasks in hazardous conditions. With these gloves, you can confidently handle slippery or oily surfaces while maintaining a secure grip, minimizing the risk of accidents and injuries

-

ENHANCED ABRASION RESISTANCE AND DEXTERITY - The sandy finish black NBR palm coating not only enhances abrasion resistance but also promotes superior dexterity. This feature enables precise handling of tools and materials, enhancing productivity and efficiency. Whether you're gripping equipment or manoeuvring through intricate tasks, these gloves offer the flexibility and agility required for comfortable and effective performance

-

VERSATILE APPLICATION FOR VARIOUS TASKS - Suitable for a wide range of tasks, these gloves offer versatility and adaptability. From industrial settings to outdoor activities, they provide the necessary protection without hindering mobility. With their sporty look and robust construction, these gloves are the go-to choice for professionals and enthusiasts alike, ensuring both safety and comfort throughout the day

Abrasion

Dexterity

EN 388

Delivery & Services

Easy Return

with our 15 days return poicy

ABOUT THE DESIGN

USEFUL IN THESE INDUSTRIES

AUTOMOBILE

CHEMICAL & PAINT

CONSTRUCTION

OIL & GAS

Resistance to abrasion based on the number of cycles required to abrade through the sample glove (abrasion by sandpaper under a stipulated pressure). The protection factor is then indicated on a scale from 1 to 4 depending on how many revolutions are required to make a hole in the material. The higher the number, the better the glove.

Blade cut resistance based on the number of cycles required to cut through the sample at a constant speed. The protection factor is then indicated on a scale from 1 to 5.

Tear resistances based on the amount of force required to tear the sample. The protection factor is then indicated on a scale from 1 to 4.

Puncture resistances based on the amount of force required to pierce the sample with a standardly sized point. The protection factor is then indicated on a scale from 1 to 4.

the test is terminated. A straight blade is loaded into the machine. Weight is added to serve as a force. The blade moves across the fabric. The blade is replaced with a new one to ensure accuracy. The sample is cut five times, each with three different loads. The distance traveled to cause cut through at various forces is recorded. The data is used to determine the load required to cut through the sample.

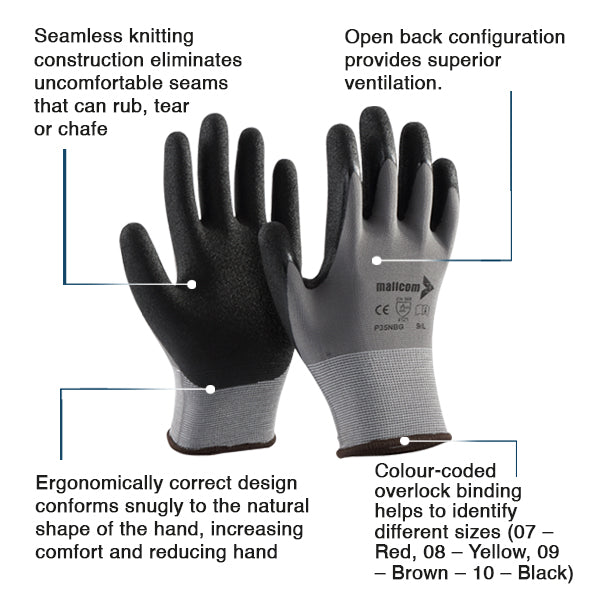

Product Features

ABOUT THE DESIGN

USEFUL IN THESE INDUSTRIES

AUTOMOBILE

CHEMICAL & PAINT

CONSTRUCTION

OIL & GAS

Product Details

Tests

Resistance to abrasion based on the number of cycles required to abrade through the sample glove (abrasion by sandpaper under a stipulated pressure). The protection factor is then indicated on a scale from 1 to 4 depending on how many revolutions are required to make a hole in the material. The higher the number, the better the glove.

Blade cut resistance based on the number of cycles required to cut through the sample at a constant speed. The protection factor is then indicated on a scale from 1 to 5.

Tear resistances based on the amount of force required to tear the sample. The protection factor is then indicated on a scale from 1 to 4.

Puncture resistances based on the amount of force required to pierce the sample with a standardly sized point. The protection factor is then indicated on a scale from 1 to 4.

the test is terminated. A straight blade is loaded into the machine. Weight is added to serve as a force. The blade moves across the fabric. The blade is replaced with a new one to ensure accuracy. The sample is cut five times, each with three different loads. The distance traveled to cause cut through at various forces is recorded. The data is used to determine the load required to cut through the sample.