D232

Share

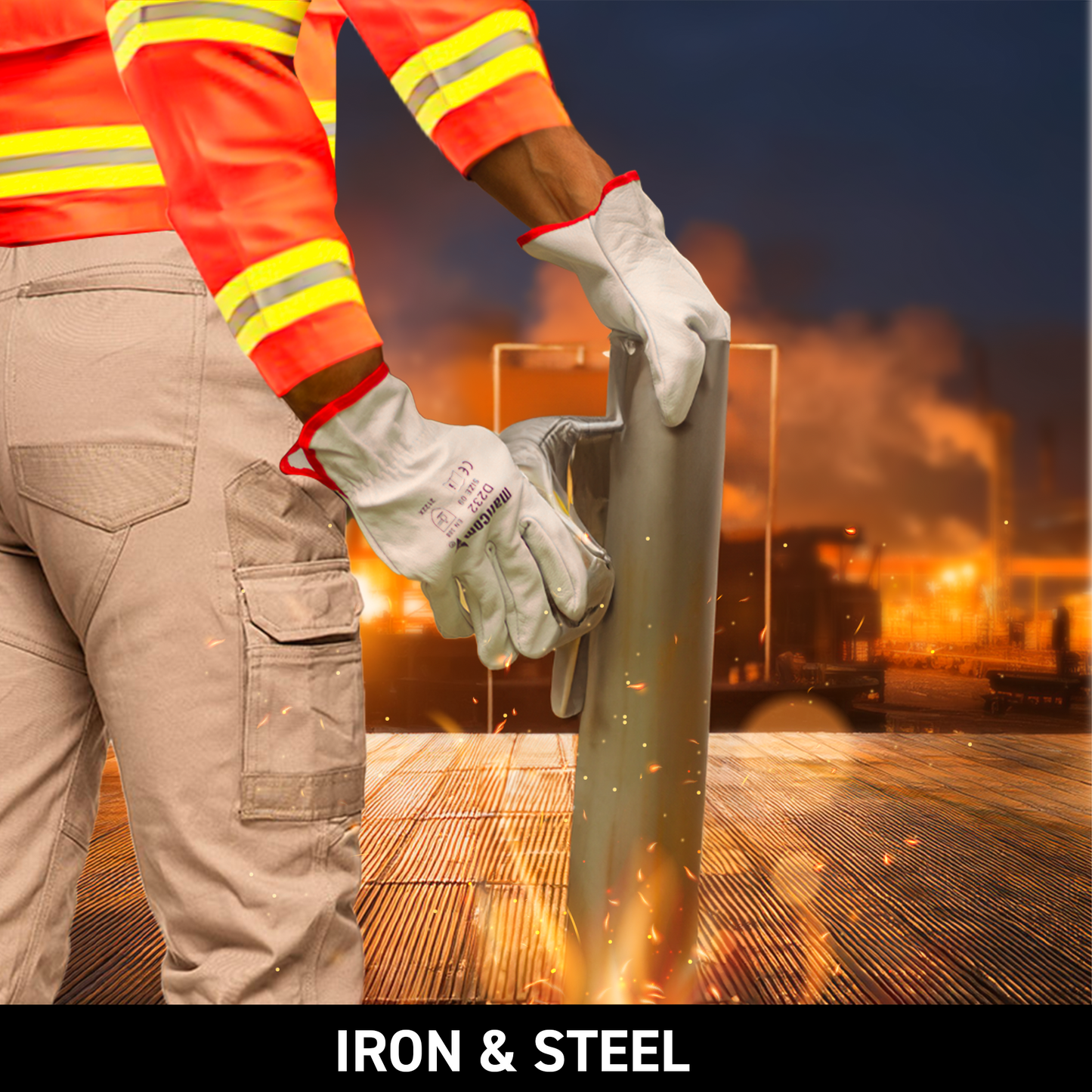

Driver Gloves

-

PREMIUM QUALITY AND COMFORT - Crafted from natural grain leather, these driver gloves offer exceptional durability and comfort. The winged thumb and elasticized back provide a snug fit and ease of movement, enhancing overall wearability. With synthetic colored binding tape at the cuff, they boast both style and functionality, making them suitable for various tasks requiring dexterity and protection

-

SUPERIOR PROTECTION AND GRIP - Tested for abrasion, blade cut resistance, tear resistance, and puncture resistance, these gloves excel in providing robust protection. Their strong grip ensures secure handling of tools and materials, reducing the risk of accidents or injuries in demanding work environments. The conducted tests validate their reliability and suitability for tasks that involve potential hazards

-

DETAILED TESTING AND PERFORMANCE METRICS- Each pair of these driver gloves undergoes rigorous testing to assess their performance under different conditions. From resistance to abrasion to blade cut resistance, tear resistance, and puncture resistance, they are evaluated on various parameters to ensure optimal protection. The TDM blade cut resistance test further verifies their ability to withstand sharp objects, providing users with confidence in their safety.

-

ASSURANCE OF DURABILITY AND SAFETY - With detailed testing procedures and performance metrics, these gloves offer assurance of durability and safety in diverse work settings. Whether used in construction, automotive, or other industrial sectors, their reliable performance and protective features make them a trusted choice for professionals seeking quality hand protection. The combination of premium materials, meticulous craftsmanship, and thorough testing ensures that these gloves meet the highest standards for durability and safety.

Abrasion

Grip

Select Size

D232

Size Chart

How to Measure

D232

D232

EN 388:2016+A1:2018

Delivery & Services

Easy Return

with our 15 days return poicy

ABOUT THE DESIGN

USEFUL IN THESE INDUSTRIES

CONSTRUCTION

IRON & STEEL

LOGISTICS

MANUFACTURING

Product Features

ABOUT THE DESIGN

USEFUL IN THESE INDUSTRIES

CONSTRUCTION

IRON & STEEL

LOGISTICS

MANUFACTURING

Product Details